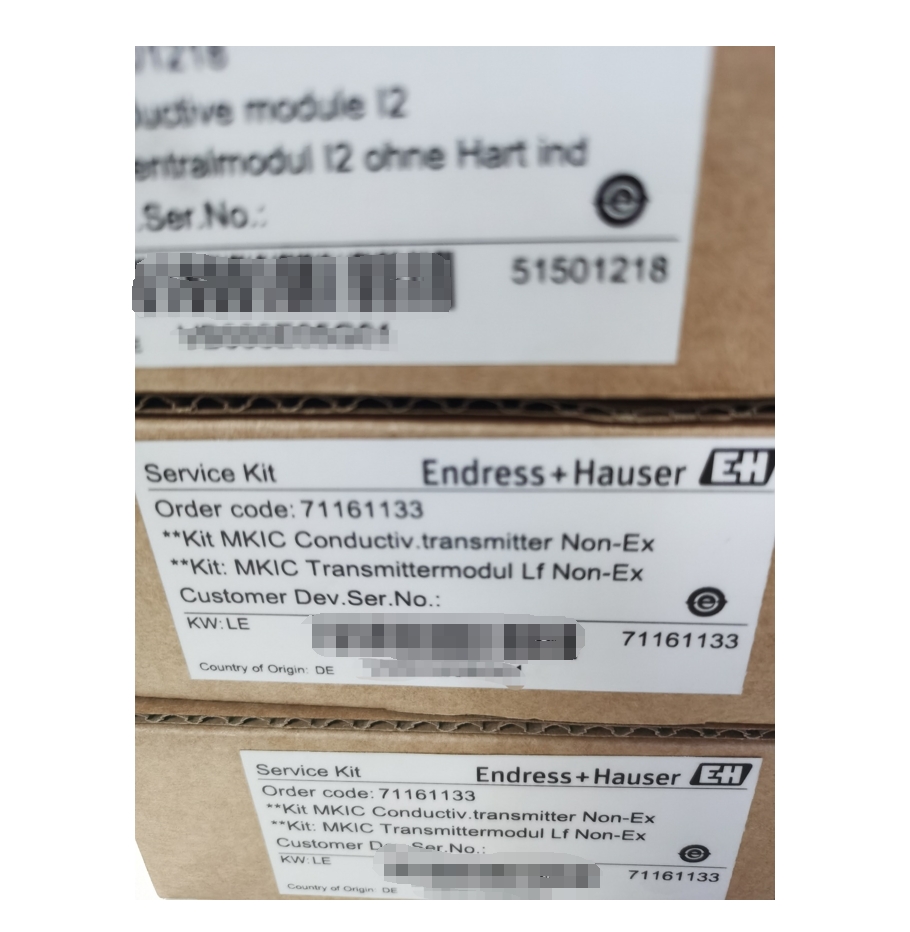

Correct use, configuration, replacement, selection, application and precautions for maintenance of the power board of the 71161133 transmitter

1161133 transmitter power board in stock in position 240

71161133 transmitter power board in stock for CPM223 CLM223 COM223 CUM223

Correct use, configuration, replacement, selection, application and precautions for maintenance of the power board of the 71161133 transmitter

71161133 transmitter are as follows,

correct use

1. Connect the power supply: correctly connect the power cord to the power board to ensure that the power supply voltage meets the requirements of the power board

2. Turn on the power: According to the requirements of the equipment, press the power switch or operate related software to start the power board

3. Monitoring status: Observe the indicator light or display of the power board to ensure that the power supply is working properly. If there is any abnormality, it should be handled in time.

4. Record data: Record the operating data of the power board, such as voltage, current, temperature, etc., as required.

5. Turn off the power: After completing the work, turn off the power or exit the relevant software according to the requirements of the equipment,

2.Configuration

1. According to the needs of the equipment, select the appropriate power board model and specifications.

2. According to the input voltage and current requirements of the power board, select the appropriate power cord model and specifications

3. According to the working environment of the equipment, configure the appropriate heat dissipation device or protection device.

4. Configure the relevant control circuit or sensor as required.

3.Replacement

1. Disconnect the power supply: Before replacing the power board, make sure that the power is disconnected, and wait for a period of time to ensure that the remaining power on the power board is completely released

2. Remove the old power board: according to the equipment structure, remove the old power board. Be careful not to damage other components or wiring,

3. Install the new power board: Insert the new power board into the device in the correct direction and position to ensure that the connection is firm

4. Connect the power cord: Connect the power cord to the new power board and make sure the connection is correct and secure

5. Test equipment: Start the equipment, check whether the new power board is working properly, and record relevant data.

6. Record replacement information: Record the time, model and other information of replacing the power board for subsequent maintenance and management.

4.selection application

1. According to the needs of the equipment, choose a power board with an appropriate input voltage and current range

2. Choose brands and models with good stability and reliability to ensure the performance and life of the power board.

3. According to the working environment of the equipment, select a power board with appropriate protection level and adaptability

4. Choose a power board with low noise, low ripple and other performance indicators to improve the electrical performance of the equipment.

5. Consider the size and weight of the power board to ensure that it is suitable for the installation and use of the equipment

6. Understand the heat dissipation performance of the power board to ensure that it can work normally in a high temperature environment.

7. Choose a power board with maintainability and easy-to-replace components for subsequent maintenance and repair.

8. In the selection process, factors such as cost performance and comprehensive cost should be fully considered to select the power board that best meets the actual needs,

5. considerations and maintenance

1. Regularly check whether the appearance and connection of the power board are normal, and deal with any abnormalities in time

2. Clean the dust and dirt on the power board regularly and keep it clean. Do not use chemical cleaners or cleaners that contain corrosive substances.

3. Pay attention to the heat dissipation of the power board and ensure that there are good heat dissipation channels or heat sinks. If there is any abnormality, it should be handled in time.

4. During use, avoid overloading or overheating to avoid damage or performance degradation. If there is any abnormality, it should be handled in time.

For more information, it is recommended to consult an expert or refer to the product description of the 71161133 transmitter power board.

a large number of in stock

welcome to buy